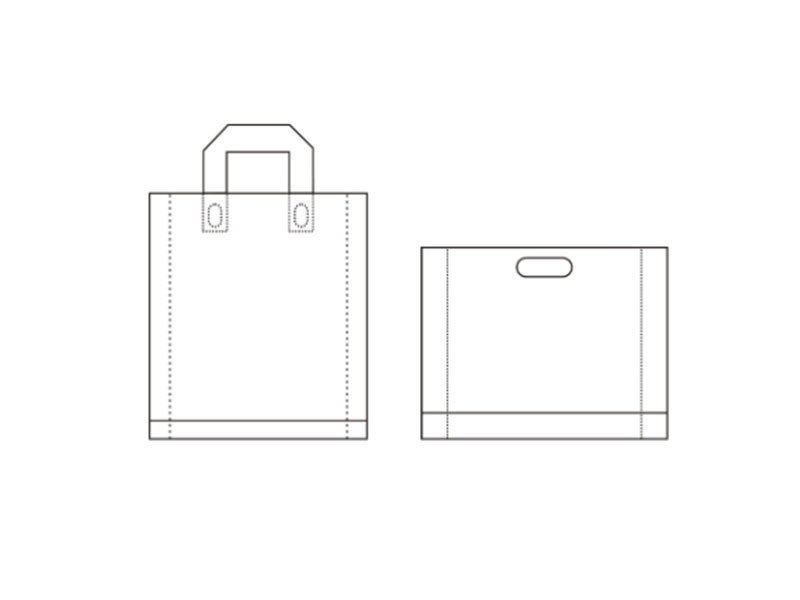

Plastic handle bag making machine

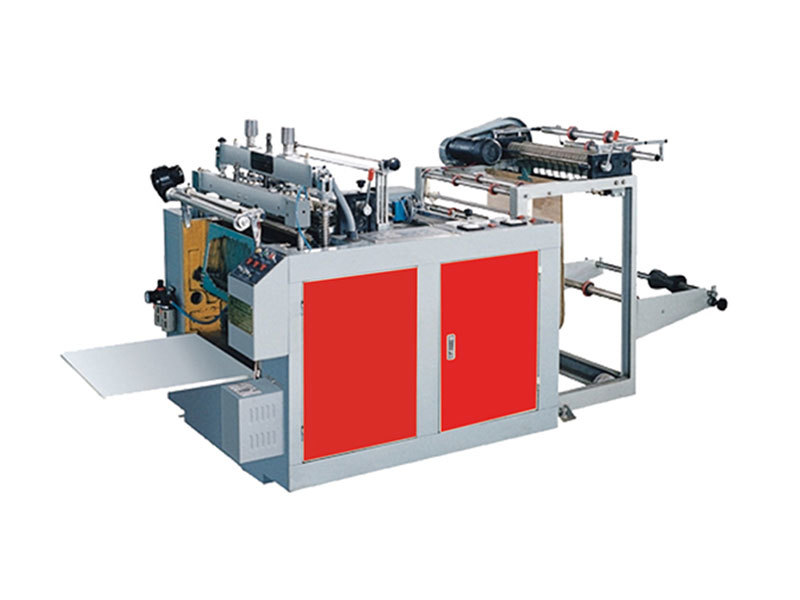

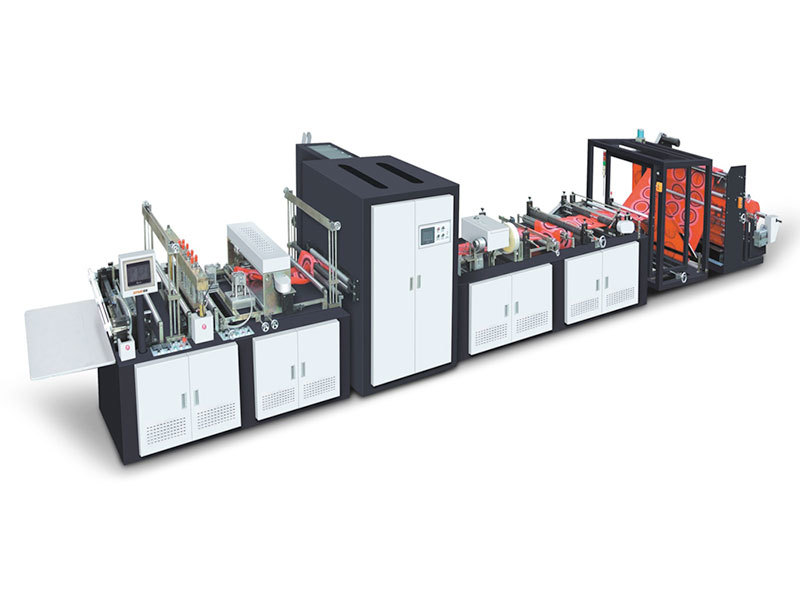

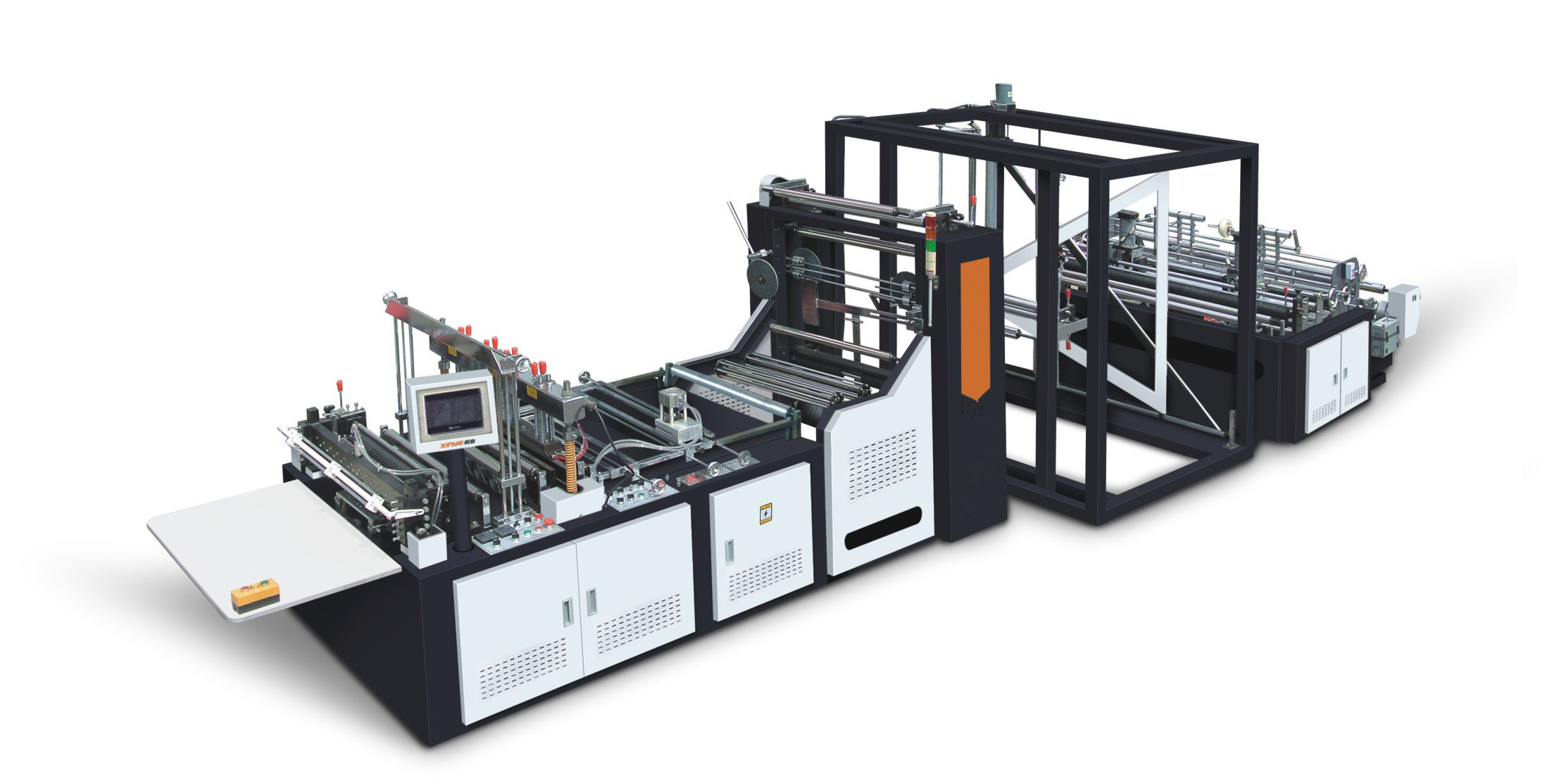

The plastic bag making machine is suitable for raw materials for plastic edging material, set motor cylinder as one, use touch screen operation, with photoelectric fixed length, photoelectric tracking, automatic positioning, automatic correction and automatic counting, and the bag hot closing part is very firm, beautiful, smooth incision without stretching, the whole machine production is stable, efficient, the machine is mainly used for the production of various types of plastic bags, Widely used in food packaging, fiber packaging, environmental protection shopping packaging and gift packaging and other industries.

Category:

Product Description

Keywords:

The plastic bag making machine is suitable for raw materials for plastic edging material, set motor cylinder as one, use touch screen operation, with photoelectric fixed length, photoelectric tracking, automatic positioning, automatic correction and automatic counting, and the bag hot closing part is very firm, beautiful, smooth incision without stretching, the whole machine production is stable, efficient, the machine is mainly used for the production of various types of plastic bags, Widely used in food packaging, fiber packaging, environmental protection shopping packaging and gift packaging and other industries.

(1) The operation control switch can be operated in the front and rear of the machine, which is simple and convenient.

(2) The tension of raw materials can be automatically adjusted during the operation of the machine (automatic tension control system is used for discharging materials).

(3) The machine adopts pneumatic feeding, convenient and simple, and the air pressure can be adjusted.

(4) Feed speed is controlled by connection switch.

(5) The hot sealing knife of the bag making machine adopts three-phase asynchronous motor, which can realize frequency conversion speed regulation.

(6) Servo no stretch, hot sealing smooth and beautiful.

(7) Spring knife cutting material, long service life.

(8) With automatic counting (bag counting or ironing counting), the number can be automatically calculated during operation.

(9) The conveying table adopts frequency conversion speed regulation, and the material is more orderly and stable.

|

Bag Width |

250-550mm |

|

Bag length |

250-600mm |

|

Max sealing width |

550mm |

|

Max Cutting width |

6500mm |

|

Max unwinding diameter |

800mm |

|

Bag thickness |

0.05-0.2mm |

|

Handle length |

330-370mm |

|

Handle width |

25-50mm |

|

speed |

45-60pcs/min |

|

power |

380v/50hz |

|

Machine size |

1000*1100*750mm |

|

Machine weight |

2500kg |

Related Products

Welcome your message consultation